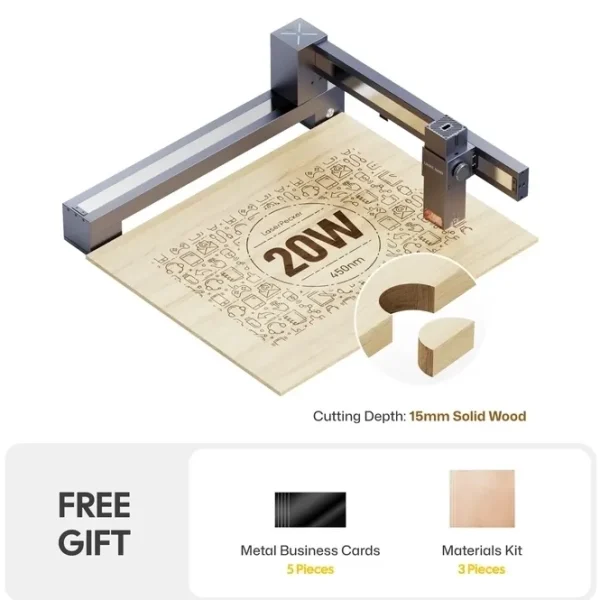

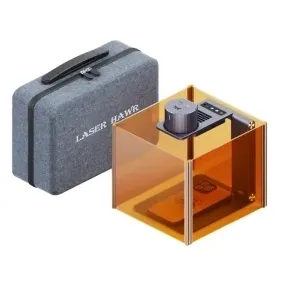

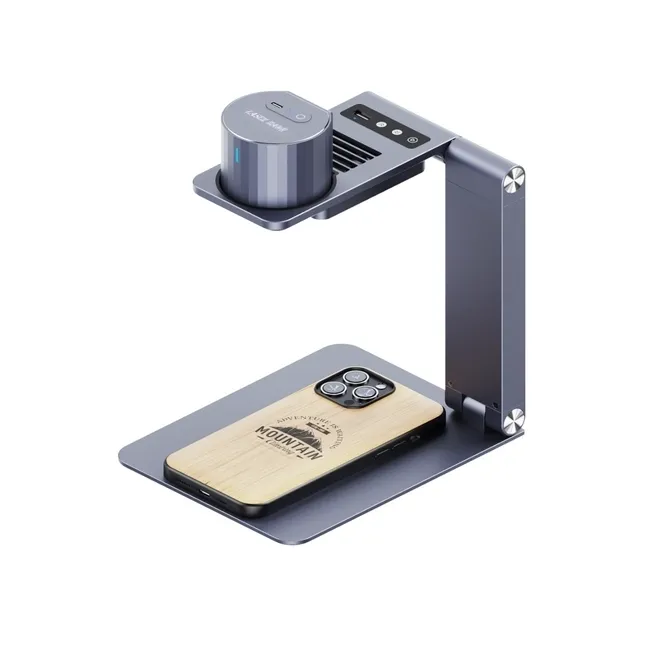

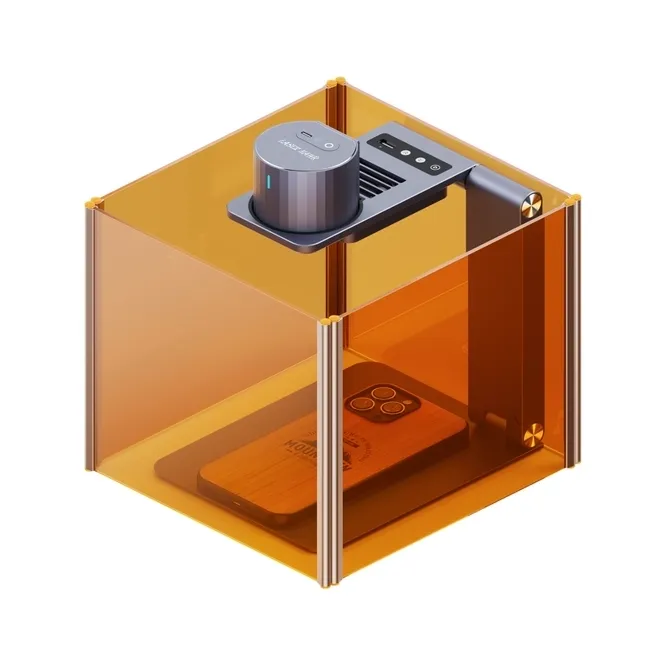

Introducing the LaserHawk LH1 Pro, the ultimate solution for precision laser engraving and cutting. Whether you’re a professional or a hobbyist, this state-of-the-art laser engraver cutter is designed to meet your every need with unmatched accuracy and efficiency.

With its advanced technology, the LaserHawk LH1 Pro excels in laser aluminium engraving, delivering crisp, detailed results on a variety of materials. From intricate designs to industrial-grade cutting, this machine is your go-to tool for all your creative and professional projects.

- High Precision: Achieve unparalleled accuracy with our cutting-edge laser technology.

- Versatility: Perfect for engraving and cutting on materials like wood, acrylic, leather, and more.

- User-Friendly: Compatible with various file formats, including DXF, AI, and SVG. Wondering what file does laser cutter use? The LaserHawk LH1 Pro supports them all!

- Durability: Built to last with high-quality components and robust construction.

Experience the future of laser engraving and cutting with the LaserHawk LH1 Pro. Elevate your craftsmanship and bring your ideas to life with this powerful and versatile machine.

Don’t settle for less—choose the best. The LaserHawk LH1 Pro is here to revolutionize your creative process.

Yuki Li –

I’m thoroughly impressed with this laser engraver! The precision and detail in engraving are exceptional, and the software is intuitive and user-friendly. It’s fast, boosting my productivity significantly. The build quality is solid, and it’s been reliable for every project. A 5-star machine for sure!

Jennifer Rodriguez –

This laser engraver offers exceptional detail and precision, with intuitive software and smooth operation. Fast engraving speeds boost efficiency, and its robust build ensures reliability. 5 stars!

Amanda Kovac (verified owner) –

**Specific Project Experience: Custom Medical Devices**

– **Project Overview:** I utilized the laser engraver to create precise engravings on titanium surgical instruments for a medical device company. The task involved engraving serial numbers and detailed instructional markings.

– **Material Behavior and Challenges:** Titanium is prone to discoloration when overheated, which posed a challenge in achieving clean, precise engravings without thermal damage.

– **Solutions Implemented:** To address overheating, we introduced controlled cooling using compressed air during the engraving process. This method ensured that the engravings were sharp and free from discoloration, maintaining both functionality and aesthetics.

**Technical Performance: Precision and Software Utilization**

– **Power Settings:** The laser engraver was set to a high power for initial marking to ensure visibility. For intricate details, lower power settings were used to prevent heat buildup and maintain precision.

– **Software Experience:** CorelDRAW was the software of choice due to its capability in vector design, offering precise control over engraving paths and depths, which was crucial for the medical device application.

– **Special Features Exploited:** The use of variable speed control and multiple pass settings allowed us to achieve consistent results across numerous instruments, ensuring each piece met stringent quality standards.

This project underscored the laser engraver’s capability in handling high-stakes applications where precision and reliability are paramount.

Lars Williams –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost efficiency. Fast, reliable, and well-built—a true workshop gem!”